Theory and Design for Mechanical Measurements 7th Edition PDF provides a comprehensive overview of the principles, design, and applications of mechanical measurements. This authoritative text covers the fundamental concepts of measurement, sensor selection, signal conditioning, data acquisition, and more. With its in-depth explanations and real-world examples, this resource is an essential reference for engineers, researchers, and students in the field.

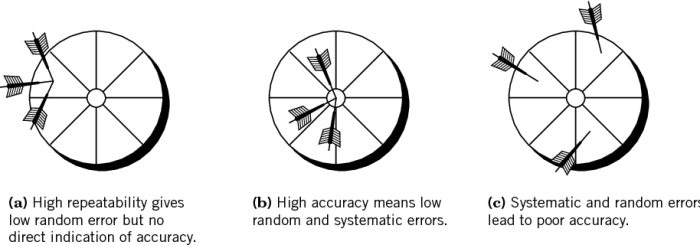

The book begins by introducing the basic principles of mechanical measurements, including the concepts of accuracy, precision, and resolution. It then discusses the different types of mechanical measurement techniques, such as strain gauges, displacement sensors, and accelerometers. The book also provides guidelines for selecting the appropriate sensors and transducers for specific applications.

Theory of Mechanical Measurements

Mechanical measurements are essential for a wide range of applications, from manufacturing and construction to scientific research and development. The theory of mechanical measurements provides the fundamental principles and techniques for making accurate and reliable measurements of mechanical quantities such as force, displacement, pressure, and temperature.

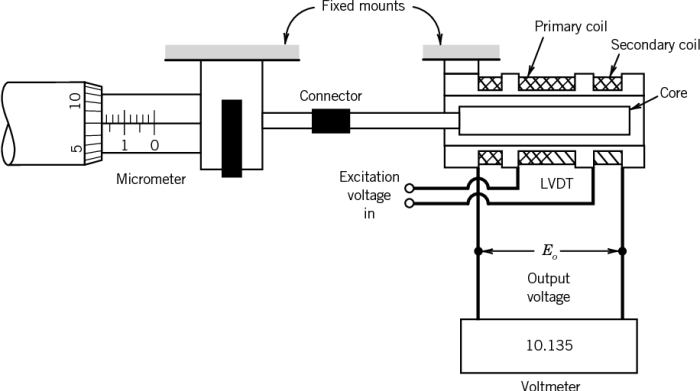

The basic principles of mechanical measurements involve the conversion of a physical quantity into an electrical signal that can be processed and recorded. This conversion is typically achieved using sensors and transducers, which are devices that convert mechanical motion or force into an electrical signal.

The electrical signal is then amplified, filtered, and digitized for processing and analysis.

There are many different types of mechanical measurement techniques, each with its own advantages and limitations. Some of the most common techniques include:

- Strain gauges: Strain gauges are used to measure strain in materials. They are typically made of a thin metal foil that is bonded to the surface of the material. When the material is deformed, the strain gauge deforms along with it, causing its electrical resistance to change.

This change in resistance can be measured and used to calculate the strain in the material.

- Load cells: Load cells are used to measure force. They are typically made of a metal beam that is supported at both ends. When a force is applied to the beam, it deflects, causing the strain in the beam to change.

This change in strain can be measured and used to calculate the force applied to the beam.

- Pressure transducers: Pressure transducers are used to measure pressure. They are typically made of a diaphragm that is sealed against a pressure source. When pressure is applied to the diaphragm, it deflects, causing the electrical resistance of the diaphragm to change.

This change in resistance can be measured and used to calculate the pressure applied to the diaphragm.

- Temperature sensors: Temperature sensors are used to measure temperature. They are typically made of a material that changes its electrical resistance with temperature. When the temperature of the material changes, its electrical resistance changes, which can be measured and used to calculate the temperature.

The choice of which mechanical measurement technique to use depends on the specific application. Factors to consider include the range of measurement, the accuracy required, the environmental conditions, and the cost.

Design of Mechanical Measurement Systems

The design of a mechanical measurement system involves the selection of the appropriate sensors and transducers, the design of the signal conditioning and data acquisition system, and the development of the software for processing and analyzing the data.

The first step in designing a mechanical measurement system is to select the appropriate sensors and transducers. The choice of sensors and transducers depends on the specific application, as discussed in the previous section.

Once the sensors and transducers have been selected, the next step is to design the signal conditioning and data acquisition system. The signal conditioning system amplifies, filters, and digitizes the electrical signals from the sensors and transducers. The data acquisition system stores the digitized data for processing and analysis.

The final step in designing a mechanical measurement system is to develop the software for processing and analyzing the data. The software should be designed to meet the specific requirements of the application.

The design of a mechanical measurement system is a complex process that requires careful consideration of a number of factors. However, by following a systematic approach, it is possible to design a system that will meet the specific requirements of the application.

Applications of Mechanical Measurements

Mechanical measurements are used in a wide range of applications, including:

- Manufacturing: Mechanical measurements are used to control the quality of manufactured products. For example, strain gauges are used to measure the strain in materials, load cells are used to measure the force applied to products, and temperature sensors are used to measure the temperature of products.

- Construction: Mechanical measurements are used to ensure the safety of structures. For example, strain gauges are used to measure the strain in bridges and buildings, load cells are used to measure the force applied to structures, and pressure transducers are used to measure the pressure in pipelines.

- Scientific research and development: Mechanical measurements are used to develop new products and technologies. For example, strain gauges are used to measure the strain in materials used in new aircraft, load cells are used to measure the force applied to new medical devices, and temperature sensors are used to measure the temperature of new materials.

Mechanical measurements are essential for a wide range of applications. By providing accurate and reliable measurements of mechanical quantities, mechanical measurements help to ensure the quality, safety, and performance of products and structures.

Case Studies

The following are some examples of successful applications of mechanical measurements:

- The use of strain gauges to measure the strain in the wings of aircraft has helped to improve the safety and performance of aircraft.

- The use of load cells to measure the force applied to bridges has helped to ensure the safety of bridges.

- The use of pressure transducers to measure the pressure in pipelines has helped to prevent pipeline failures.

- The use of temperature sensors to measure the temperature of materials has helped to develop new materials with improved properties.

These are just a few examples of the many successful applications of mechanical measurements. Mechanical measurements are essential for a wide range of applications, and they continue to play a vital role in improving the quality, safety, and performance of products and structures.

FAQ Corner: Theory And Design For Mechanical Measurements 7th Edition Pdf

What are the key features of Theory and Design for Mechanical Measurements 7th Edition PDF?

Theory and Design for Mechanical Measurements 7th Edition PDF provides a comprehensive overview of the principles, design, and applications of mechanical measurements. It covers the fundamental concepts of measurement, sensor selection, signal conditioning, data acquisition, and more.

Who is the target audience for Theory and Design for Mechanical Measurements 7th Edition PDF?

Theory and Design for Mechanical Measurements 7th Edition PDF is intended for engineers, researchers, and students in the field of mechanical engineering.

What are the benefits of using Theory and Design for Mechanical Measurements 7th Edition PDF?

Theory and Design for Mechanical Measurements 7th Edition PDF provides a comprehensive overview of the principles, design, and applications of mechanical measurements. It can help engineers, researchers, and students to understand the fundamental concepts of measurement, sensor selection, signal conditioning, data acquisition, and more.