Delve into the intricacies of the Scott SCBA Regulator Parts Diagram, an indispensable resource for understanding the assembly, maintenance, and safety protocols of this crucial equipment. Our comprehensive guide empowers you with the knowledge to ensure the optimal performance and longevity of your SCBA regulator, safeguarding your well-being in critical situations.

This detailed guide provides a comprehensive overview of the regulator’s components, their functions, and their precise placement within the assembly. Step-by-step instructions guide you through the assembly and disassembly processes, accompanied by clear illustrations for visual clarity. Additionally, we cover essential maintenance procedures and troubleshooting techniques to address common issues promptly.

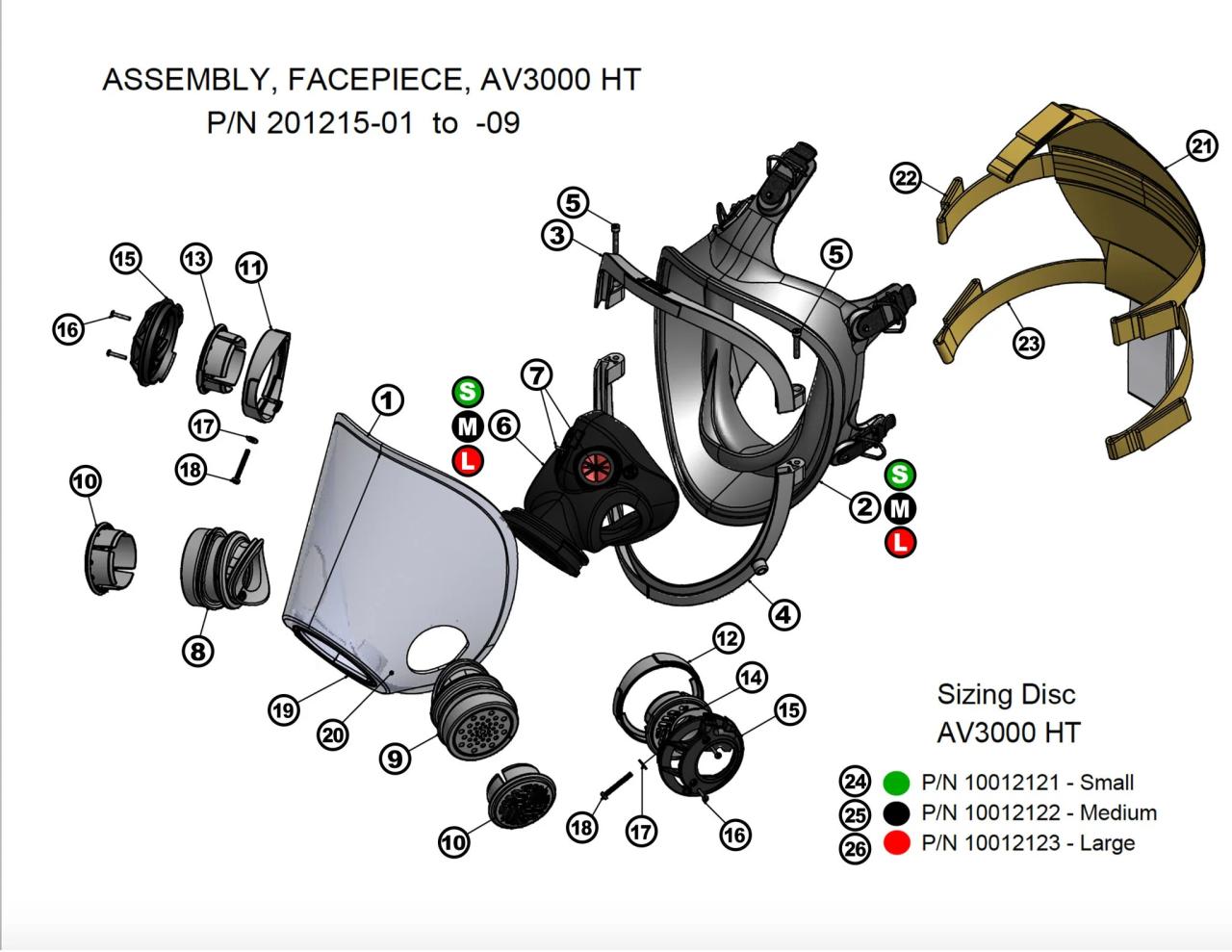

Parts Overview

The SCOTT SCBA Regulator assembly comprises various components that collectively ensure the safe and efficient delivery of breathing gas to the user. These parts can be broadly categorized into housing, diaphragm, and valve assembly.

Housing

The housing of the regulator serves as a protective enclosure for the internal components. It is typically made of durable materials like metal or composite polymers to withstand the rigors of firefighting operations. The housing consists of the following parts:

- Body: The main housing structure that encloses the diaphragm and valve assembly.

- Inlet Port: The connection point for the high-pressure breathing gas supply.

- Outlet Port: The connection point for the breathing hose that delivers gas to the user.

Assembly and Disassembly s: Scott Scba Regulator Parts Diagram

The SCOTT SCBA Regulator is a critical component of the SCBA system, ensuring the proper functioning of the breathing apparatus. Understanding the assembly and disassembly procedures is essential for maintaining the regulator’s optimal performance and safety.

Before beginning any assembly or disassembly, ensure you have the necessary tools, a clean workspace, and a thorough understanding of the regulator’s components.

Assembly Procedure

- Lubricate all O-rings and gaskets with a suitable lubricant.

- Align the first stage diaphragm with the regulator body and secure it with the diaphragm retaining ring.

- Install the second stage diaphragm and secure it with the diaphragm retaining ring.

- Attach the yoke to the regulator body and tighten it securely.

- Connect the high-pressure hose to the first stage outlet.

- Connect the low-pressure hose to the second stage outlet.

- Install the demand valve and mouthpiece assembly.

- Adjust the regulator settings as per manufacturer’s specifications.

Disassembly Procedure

- Depressurize the regulator by opening the cylinder valve and breathing out through the mouthpiece.

- Disconnect the high-pressure and low-pressure hoses.

- Remove the demand valve and mouthpiece assembly.

- Unscrew the yoke from the regulator body.

- Remove the diaphragm retaining rings and diaphragms.

- Inspect all components for wear or damage.

- Replace any worn or damaged components with genuine SCOTT parts.

Safety Precautions

- Always wear appropriate safety gear, including gloves and eye protection.

- Do not attempt to disassemble the regulator if you are not trained or certified.

- Use only genuine SCOTT parts and lubricants.

- Follow all manufacturer’s instructions carefully.

- Have the regulator inspected and serviced by an authorized SCOTT technician regularly.

Maintenance and Troubleshooting

To ensure optimal performance and safety, the SCOTT SCBA Regulator requires regular maintenance and troubleshooting. Routine maintenance procedures and common troubleshooting steps are Artikeld below.

Routine Maintenance Procedures, Scott scba regulator parts diagram

Routine maintenance includes regular inspection, cleaning, and lubrication of the regulator. Inspections should be performed before each use to identify any visible damage or wear. Cleaning should be performed as per the manufacturer’s recommendations, using mild detergents and soft brushes to remove dirt and debris.

Lubrication should be performed using only the specified lubricants recommended by the manufacturer.

Common Problems and Troubleshooting

Common problems that may occur with the SCOTT SCBA Regulator include:

- Leaking regulator:Inspect the regulator for any cracks or damage. Tighten any loose connections and replace any damaged parts as necessary.

- Reduced airflow:Check the air filter for clogs and clean or replace as needed. Inspect the regulator for any obstructions and clear as necessary.

- Difficulty breathing:Check the regulator for any blockages or restrictions. Ensure that the regulator is properly connected to the air supply and that the breathing hose is not kinked or obstructed.

If the problem persists after following the troubleshooting steps, contact a qualified technician for further assistance.

Safety Considerations

Proper use and maintenance of the SCOTT SCBA Regulator are crucial for user safety. Incorrect usage or malfunction can pose significant hazards, including:

-

-*Respiratory distress or failure

Incorrect use or a malfunctioning regulator can compromise breathing gas supply, leading to respiratory distress or failure.

-*Exposure to hazardous gases

A faulty regulator may fail to filter out hazardous gases, exposing the user to harmful substances.

-*Physical injury

A malfunctioning regulator can cause physical injury if it ruptures or malfunctions during use.

Safe Handling and Storage

To ensure safe handling and storage:

-

-*Follow manufacturer’s instructions

Carefully read and follow the manufacturer’s instructions for proper use, maintenance, and storage.

-*Inspect before use

Always inspect the regulator and its components before each use for any signs of damage or malfunction.

-*Store in a clean, dry environment

Store the regulator in a clean, dry environment when not in use to prevent corrosion or contamination.

-*Keep away from heat and direct sunlight

Avoid exposing the regulator to excessive heat or direct sunlight, as it can damage the materials.

-*Train and certify users

Ensure that users are properly trained and certified to use the regulator safely.

Specifications and Technical Data

The SCOTT SCBA Regulator is engineered to meet the highest standards of safety and performance. Its technical specifications are meticulously designed to ensure optimal operation in demanding environments.

The following table summarizes the key technical specifications of the SCOTT SCBA Regulator:

| Specification | Value |

|---|---|

| Pressure Rating | 2216 psi (153 bar) |

| Flow Rate | Up to 130 liters per minute |

| Materials of Construction | Brass, stainless steel, aluminum |

These specifications play a critical role in the safe and effective operation of the SCOTT SCBA Regulator:

- Pressure Rating:The pressure rating of 2216 psi (153 bar) ensures that the regulator can withstand the high pressures encountered in SCBA systems, providing reliable performance even in extreme conditions.

- Flow Rate:The flow rate of up to 130 liters per minute ensures that the regulator can deliver sufficient airflow to meet the demands of the user, even during strenuous activities.

- Materials of Construction:The use of high-quality materials such as brass, stainless steel, and aluminum ensures durability, corrosion resistance, and longevity of the regulator.

Detailed FAQs

What is the purpose of the diaphragm in the Scott SCBA Regulator?

The diaphragm is a critical component that separates the high-pressure gas from the low-pressure gas within the regulator, ensuring precise pressure regulation.

How often should I inspect the O-rings in my SCBA Regulator?

Regular inspection of O-rings is crucial. Inspect them visually for any signs of damage or wear before each use and replace them as needed to maintain a leak-proof seal.