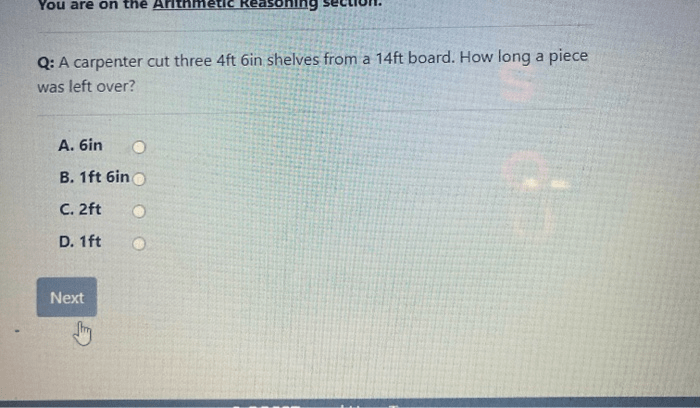

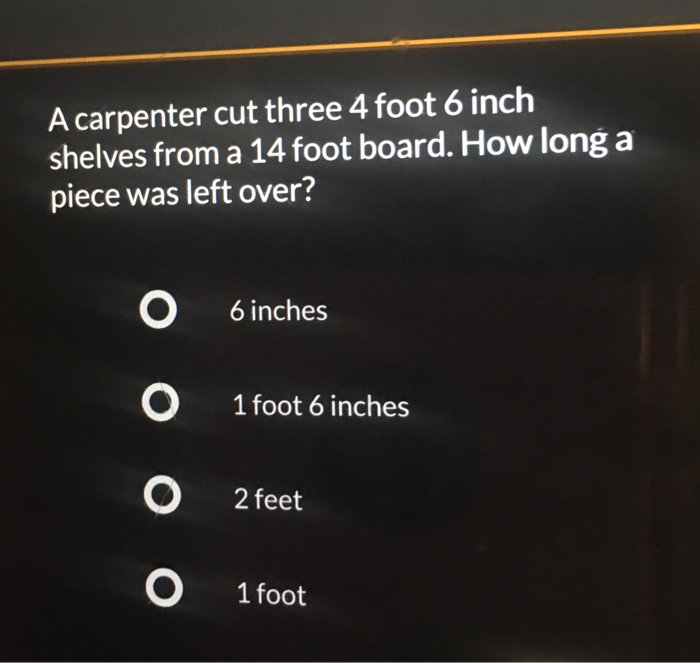

In the world of carpentry, precision and accuracy are paramount. A carpenter cut three 4ft 6in is a testament to the importance of measuring, cutting, and using lumber correctly. This comprehensive guide will delve into the techniques, safety precautions, and applications of this specific length of lumber, empowering you to tackle your carpentry projects with confidence.

Whether you’re a seasoned professional or a novice woodworker, this guide will provide valuable insights and practical tips to help you achieve clean, precise cuts and build sturdy, long-lasting structures.

Measuring and Marking

Accurate measurements are crucial for precise wood cutting. Mismeasurements can lead to wasted materials, poor-fitting joints, and overall project failures.

Measuring

- Use a measuring tape or ruler with clear markings and graduations.

- Measure twice to confirm the length before marking.

- Mark the measurement clearly on the wood using a pencil or marking knife.

Marking

- Square off the end of the wood to ensure a straight cut.

- Use a combination square or T-bevel to mark perpendicular lines.

- Double-check the markings before cutting to avoid mistakes.

Cutting Techniques: A Carpenter Cut Three 4ft 6in

Cutting is a fundamental skill in carpentry, requiring precision and accuracy. Carpenters employ various cutting techniques, each tailored to specific tasks and materials. Understanding these techniques empowers carpenters to achieve clean, precise cuts essential for building projects.

Crosscutting

Crosscutting involves cutting across the grain of the wood, perpendicular to its fibers. This technique is commonly used for cutting boards to length, squaring ends, and creating tenons. Essential tools for crosscutting include a miter saw, circular saw, or hand saw.

A carpenter had cut three 4ft 6in planks, a common measurement in woodworking. However, for a more in-depth exploration of the fantasy realm, you might want to delve into the hobbit summary chapter 2 . Returning to our carpenter, the planks were destined for a project that required precise cutting.

For clean and accurate crosscuts, ensure the saw blade is sharp and perpendicular to the wood surface. Use a miter gauge or fence to guide the saw for precise angles. Hold the workpiece firmly and apply moderate pressure to prevent splintering or tear-out.

Ripping

Ripping involves cutting along the grain of the wood, parallel to its fibers. This technique is often used for creating boards of specific widths, cutting grooves, or resawing lumber. Ripping requires a table saw or circular saw with a ripping blade.

Achieving clean and accurate rips requires a sharp blade and a sturdy fence to guide the wood. Secure the workpiece firmly to prevent kickback and ensure a straight cut. Use a featherboard or anti-kickback pawls for added safety and stability.

Mitering

Mitering involves cutting angles on the ends of wood pieces to create joints that form corners. This technique is commonly used in picture frames, crown molding, and decorative trim. A miter saw is the primary tool for mitering.

For precise miter cuts, ensure the saw blade is sharp and the miter gauge is set to the correct angle. Use a stop block or fence to ensure consistent angles across multiple pieces. Secure the workpiece firmly and apply moderate pressure to prevent chipping or tear-out.

Safety Precautions

When operating power tools, safety should always be your top priority. Neglecting proper safety measures can lead to severe injuries or even fatalities. To ensure a safe and productive work environment, adhering to the following precautions is essential.

Essential Safety Precautions:

- Wear appropriate safety gear:Always wear eye protection, earplugs or ear muffs, a dust mask, and gloves when using power tools.

- Use sharp blades:Dull blades can cause the tool to slip or bind, increasing the risk of injury. Ensure your blades are sharp and in good condition.

- Maintain a clean work area:Cluttered workspaces can lead to accidents. Keep your work area clean and free of debris, and ensure adequate lighting.

Common Hazards and Prevention

Common Hazards:

- Kickback:Occurs when the workpiece is suddenly thrown back towards the operator. It can be caused by using a dull blade, improper workpiece support, or incorrect cutting technique.

- Electrical shock:Can result from using damaged tools or working in wet or damp conditions. Ensure your tools are in good condition and use proper grounding techniques.

- Cuts and lacerations:Can occur from contact with sharp blades or flying debris. Always wear appropriate safety gear and handle tools with care.

Prevention:

- Use sharp blades and ensure proper workpiece support to prevent kickback.

- Inspect tools regularly for damage and use proper grounding techniques to prevent electrical shock.

- Wear appropriate safety gear and handle tools with care to avoid cuts and lacerations.

Applications and Uses

4ft 6in. lumber, commonly known as “studs,” is a versatile material widely used in carpentry. Its specific length makes it ideal for various applications, particularly in framing, cabinetry, and furniture making.

Framing

In framing, 4ft 6in. studs are primarily used to construct walls and partitions. They provide structural support and define the shape of the building. The length is convenient for creating standard 8ft walls when used in pairs, with a 2×4 plate on top and bottom.

Cabinetry

In cabinetry, 4ft 6in. lumber is commonly used for building cabinet frames and carcasses. The length is suitable for creating standard-sized cabinets, such as base cabinets and wall-mounted units. It provides a sturdy base for installing shelves, drawers, and doors.

Furniture Making

In furniture making, 4ft 6in. lumber is often used for constructing tables, chairs, and other pieces. The length is ideal for creating legs, aprons, and stretchers. It provides stability and durability to the furniture.

Advantages and Disadvantages

Using 4ft 6in. lumber offers several advantages:

- Versatility:Can be used in a wide range of carpentry applications.

- Availability:Readily available at most lumberyards and home improvement stores.

- Cost-effective:Relatively affordable compared to longer lumber.

However, it also has some disadvantages:

- Limited Length:May not be suitable for projects requiring longer lumber.

- Need for Jointing:May require joining multiple pieces for larger projects.

Variations and Alternatives

4ft 6in. lumber comes in a variety of variations and alternatives, including different wood species, grades, and alternative materials.

Wood Species

4ft 6in. lumber is available in various wood species, each with its unique properties and characteristics. Common wood species used for 4ft 6in. lumber include:

- Pine: A softwood known for its affordability, workability, and versatility.

- Fir: A softwood with good strength and durability, suitable for outdoor applications.

- Redwood: A durable and rot-resistant softwood, ideal for outdoor projects.

- Cedar: A naturally decay-resistant softwood, often used for decks and siding.

- Oak: A hardwood with exceptional strength and durability, suitable for heavy-duty applications.

Wood Grades

4ft 6in. lumber is also available in different grades, which indicate its quality and appearance. Common wood grades include:

- Select: The highest grade, with minimal defects and a smooth surface.

- No. 1: A high-quality grade with few defects and a generally smooth surface.

- No. 2: A lower-quality grade with more defects and a rougher surface.

- Utility: The lowest grade, with significant defects and a rough surface.

Alternative Materials

In addition to wood, there are several alternative materials that can be used in place of 4ft 6in. lumber, including:

- Metal: Metal beams and channels can provide high strength and durability, but are typically more expensive than wood.

- Composite materials: Composite materials, such as fiberglass and plastic, offer durability and resistance to moisture and insects, but can be more expensive than wood.

| Material | Strength | Durability | Cost | Applications |

|---|---|---|---|---|

| Wood | Moderate | Moderate | Affordable | General construction, framing, furniture |

| Metal | High | High | Expensive | Structural support, bridges, heavy-duty applications |

| Composite materials | Moderate to high | High | Expensive | Decks, siding, outdoor furniture |

Design Considerations

When using 4ft 6in. lumber, certain design considerations must be taken into account to ensure the strength and stability of the structure. The length of the lumber can significantly impact the overall integrity of the project.

Span Limitations

The length of the lumber determines the maximum span it can support without excessive deflection or sagging. For 4ft 6in. lumber, the recommended maximum span for floor joists is 7ft 6in., while for ceiling joists it is 8ft 6in. Exceeding these spans may require additional support, such as beams or trusses, to prevent structural failure.

Strength Considerations

The strength of the lumber is also influenced by its length. Longer lumber is more susceptible to bending and buckling under load compared to shorter pieces. When designing with 4ft 6in. lumber, it is crucial to consider the load-bearing capacity of the structure and select lumber with an appropriate grade and strength rating.

Design Tips

To effectively utilize 4ft 6in. lumber in construction projects, consider the following design tips:

-

-*Use continuous spans

Avoid splicing or joining lumber over supports, as this can weaken the structure.

-*Provide adequate support

Ensure proper support for the ends of the lumber by using joist hangers, beams, or other structural elements.

-*Consider load distribution

Distribute the load evenly across the lumber by using multiple supports or by incorporating bracing elements.

-*Select appropriate lumber grade

Choose lumber with a grade that meets the specific requirements of the project in terms of strength and durability.

By following these design considerations and incorporating sound construction practices, you can effectively utilize 4ft 6in. lumber to create strong and stable structures.

Cost and Availability

The cost and availability of 4ft 6in. lumber vary depending on factors such as the type of wood, supplier, and market conditions. Here’s an overview of what to expect:

Price Range

- Generally, 4ft 6in. lumber costs more than shorter lengths due to the increased material and processing required.

- Hardwoods, such as oak or mahogany, tend to be more expensive than softwoods, like pine or fir.

- Prices can fluctuate based on supply and demand, especially during peak construction seasons.

Suppliers

You can find 4ft 6in. lumber at most hardware stores, lumber yards, and online retailers. It’s recommended to compare prices from different suppliers to get the best deal.

Availability, A carpenter cut three 4ft 6in

4ft 6in. lumber is generally available in most regions. However, it may be less common than shorter lengths, so it’s advisable to check with suppliers before making a purchase.

FAQ Corner

What is the best way to measure and mark lumber for cutting?

Use a measuring tape and pencil to accurately mark the desired length on the lumber. Double-check your measurements before making any cuts.

What are the different cutting techniques used in carpentry?

Common cutting techniques include crosscutting (cutting across the grain), ripping (cutting with the grain), and mitering (cutting angles for joints).

What safety precautions should I take when using power tools?

Wear appropriate safety gear, such as safety glasses, gloves, and ear protection. Use sharp blades and maintain a clean work area to minimize hazards.